Machining is always about speed, precision, and reliability but in the extremely competitive manufacturing environment, efficiency is everything. If you are producing components for the aerospace industry, automotive components or high-tech products the tools you choose directly affect the bottom line of your business. Drills that can be indexable, high-speed drills, tungsten-carbide end mills and threading inserts are all essential.

Image credit: stwang-tw.com

They aren’t just upgrades to older tools. They are a better way to work reducing the amount of downtime, cutting costs overall and producing better results without a lot of effort. Take a look at each of them to see how they can help companies drill more deeply, cut cleanly, and finish quicker.

Indexable Drills: More Holes, Less Hassle

Drilling large holes could cost a lot of time and money. Drills made of solid material wore out rapidly, needed sharpening, and, in many cases, caused delays in production lines. This is one reason why more machinists have been changing to the indexable drill. When the drill becomes dull, instead of replacing the whole tool you can simply change the cutting inserts.

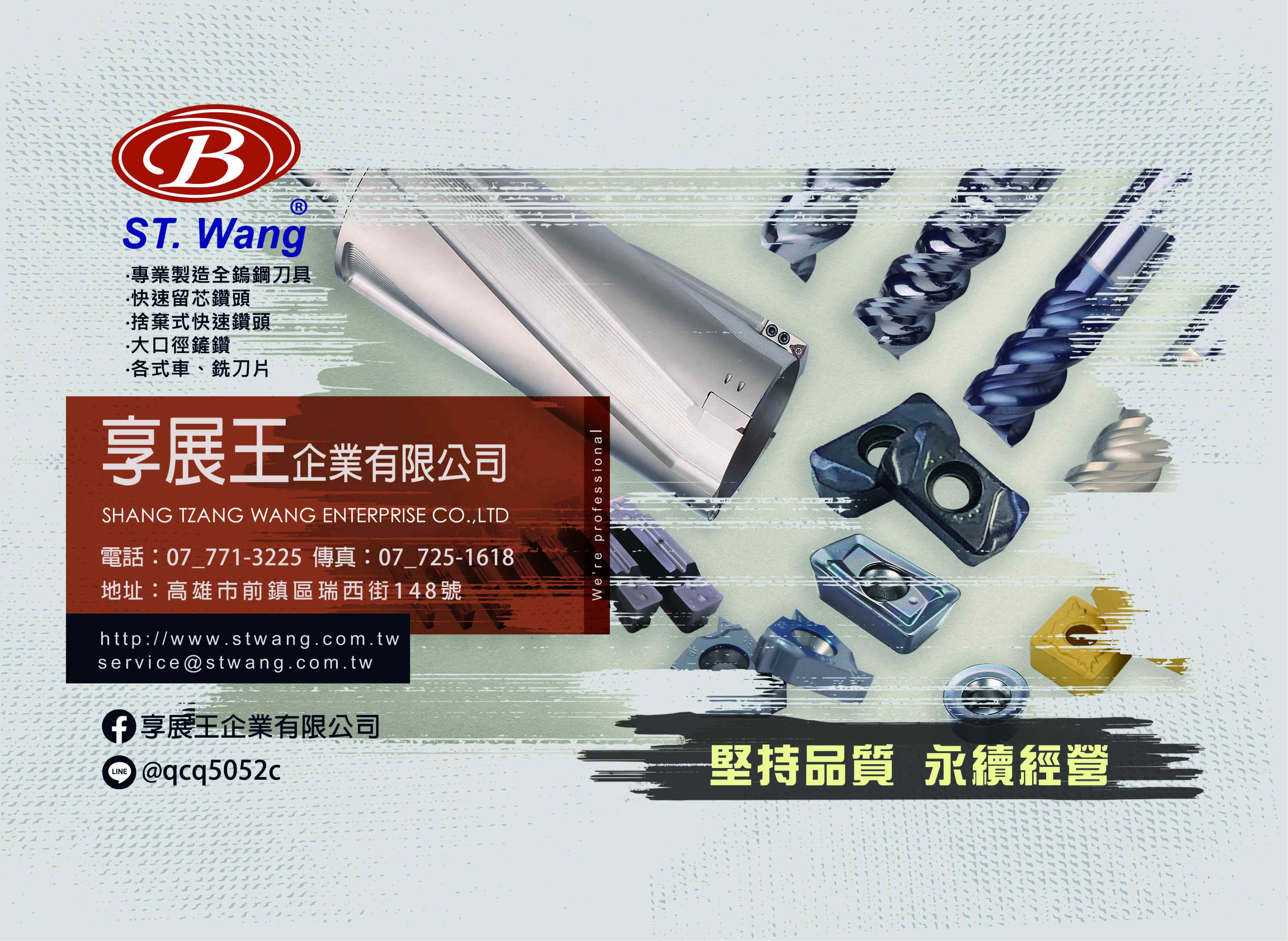

Indexable drills are known for their high efficiency. They’re built for long runs, performance that is heavy-duty and are easy to maintain. With inserts that can be replaced that reduce the amount of waste, decrease inventory of tools and keep machines running longer. SHANG TZANG WANG ENTERPRISE CO., LTD, offers cutting-edge core-stay drills made of disposable material that offer consistent performance even in large-diameter applications. This upgrade reduces downtime for shops that perform repeated hole machining.

High Speed Drills are Designed to meet the demands of today.

In a production environment in which time is a major factor, high speed drills are designed to speed up the process but without sacrificing accuracy. They are ideal for products that have high resistance and fast cycle times. They can be used to make everything from large-volume automotive parts to high-precision medical equipment.

Modern high speed drills feature optimized flute designs and cutting-edge coatings that resist thermal buildup, minimize friction, and prolong tool life. This means fewer breakages more tool maintenance, and more parts out the doors. For any machinist who’s felt the frustration of a broken drill mid-cycle, switching to a high speed drill can feel like a revelation.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

In the realm of milling, tungsten carbide-based end mills are the kings of the shop floor. They are renowned for their toughness and heat resistance as well as their ability to cut through tough materials without losing sharpness. These tools are reliable to complete any job such as roughing large sections to finishing corners.

The flexibility of the tungsten carbide mills is what makes them so special. They can be customized to suit many different needs that range from aluminum to titanium and come with various flute counts and helix angles. For machinists who need both quality and endurance, carbide end mills are the perfect balance between the removal of material and clean surface finishes.

Threading Inserts: Tiny Tools, Big Impact

Threads’ creation might seem like an insignificant part of a procedure, but it is among the most vital aspects. A poor thread can ruin an item that is otherwise perfectly. An insert of high-quality is essential. These tools, which are small and replaceable, are specifically designed to cut internal or external threads with incredible precision and repeatability.

In contrast to traditional taps and tools that wear unevenly the threading inserts deliver the same results over a number of cycles. If one cutting edge becomes dull, just move the tool to the next point of cutting. It’s not necessary to remove or re-grind the tool. It’s quick, economical, and clear. Machinists appreciate threading inserts not only for their speed, but for their reliability. You can be confident that your threads will be able fit right from the beginning. There’s no second attempts, no rework and no worry about rejecting parts.

The Bottom Line

Modern machining is highly time-sensitive. You can’t waste it. Today’s most efficient shops are shifting towards more efficient and more adaptable tools. These advanced cutting tools don’t just increase accuracy, they streamline workflows, speed up changeovers and prolong the usable life of tools. What’s the end result? The results? Less time spent on troubleshooting, and more time is focused on creating precision parts. In a world where greater demand and a tighter margin are commonplace, tools that can work more efficiently give manufacturers the competitive edge.